London:

Nationwide:

Choosing the Right Sandpaper for Edge Sanding

Posted on September 1, 2023

Edge sanding

Choosing the Right Sandpaper for Edge Sanding: An Essential Guide

Edge sanding is a task that, for the dedicated craftsman, walks a fine line between technique and artistry. The edges of a piece of wood are as critical as the surface itself. Just like one wouldn’t wear a well-tailored dress or suit without paying attention to the seams, when crafting with wood, one shouldn’t overlook the edges. The edge reflects your dedication, your attention to detail, and, in many ways, your craftsmanship’s signature. For those unfamiliar with my style, I’m a keen advocate for doing things with precision, passion, and purpose. And with sanding, it’s no different. The world of sandpapers can be overwhelming, but fear not, for in today’s guide, I shall illuminate the path towards selecting the perfect sandpaper for edge sanding.

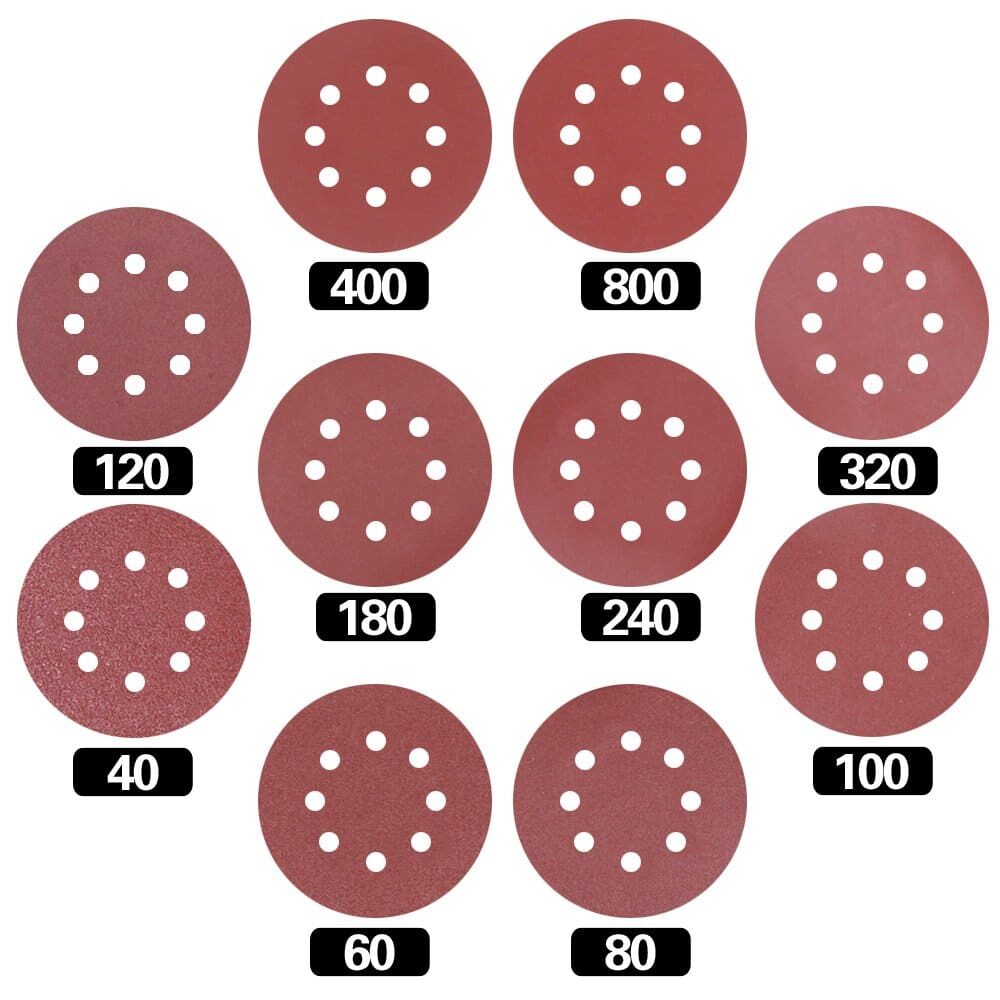

1. Understanding Grit Numbers

Before we proceed to the nitty-gritty (pun fully intended!), it’s crucial to understand what those numbers on the back of the sandpaper mean. The grit number represents the number of abrasive particles per inch. Lower numbers, like 40 or 60, mean coarser paper, useful for heavy stripping. Higher numbers, like 240 or 320, are finer and are used for finishing touches. For edge sanding, you’d want a range. Starting with a medium grit (around 80–120) to shape the edge, moving to finer grits (180–220) for smoothing, and culminating in very fine grits (320+) for the finishing touches.

2. Grain Matters

The abrasive particles on sandpaper are usually made of one of four materials: aluminium oxide, garnet, silicon carbide, or ceramic. For our edge sanding needs, the two we’re most interested in are aluminium oxide and silicon carbide. Aluminium Oxide: Durable and long-lasting, this is your go-to for general-purpose sanding. Its brownish-red hue is not just pretty to look at; this sandpaper does wonders on wood edges, keeping them sharp and well-defined. Silicon Carbide: When you desire a finish as smooth as a cup of Earl Grey, silicon carbide, with its grey or black appearance, is your choice. It’s perfect for those final stages, especially on harder woods.

3. Paper or cloth backing

Traditional sandpaper uses paper as a backing, which is adequate for most tasks. However, when you’re focusing on edges, which might require more flexibility and durability, cloth-backed sandpapers are a superior choice. They resist tearing, making them especially useful for those intricate edge jobs.

4. Technique and the Right Tool

Choosing the right sandpaper is just one part of the equation. Employing the right technique ensures that the sandpaper does its job well. Always sand in the direction of the grain. Going against it can cause scratches, which, believe me, are a sight for sore eyes! Moreover, consider the tool you’re using. For edge sanding, hand-held sanding blocks or edge sanders are recommended. They provide better control and precision.

5. Let’s talk about wet sanding.

Now, if you fancy a detour into the land of impeccable finishes, wet sanding is a technique you might want to explore. This involves using waterproof sandpaper (often silicon carbide) and a small amount of water. The water acts as a lubricant, reducing friction and aiding in achieving an ultra-smooth finish. Remember, this technique requires patience, so brew yourself a good pot of tea and take your time.6. The environmental concern

In today’s age, we must address the environmental implications of our choices. When buying sandpaper, look for brands that have a commitment to sustainable forestry. Opt for those using recycled materials or backing from managed timber resources. It’s a small choice, but remember, every oak tree was once an acorn!7. The Emotional Aspects of Sanding

It’s easy to focus solely on the technicalities, but let’s take a moment to consider the emotional connection we have with our craft. Sanding, especially edge sanding, is therapeutic for many. The repetitive motion and the gradual transformation from rough to smooth mirror many life processes where time and patience lead to refinement. When you’re sanding, you’re not just working on a piece of wood; you’re connecting with its essence, understanding its grain and imperfections, and bringing out its best. This can be a deeply satisfying and almost meditative experience. Embrace this. Allow the act of sanding to be a moment of calmness in your otherwise hectic day.8. Safety First: Protecting Yourself During Sanding

Safety is paramount. While sanding, especially edge sanding, might seem harmless, there are a few key precautions to keep in mind: Eye Protection: Even the finest particles can irritate the eyes. Always wear safety goggles to prevent any wood dust or particles from reaching your eyes. Respiratory Protection: Wood dust isn’t something you want in your lungs. A simple face mask can make a significant difference, especially if you’re sanding for prolonged periods. Workspace Ventilation: Ensure that your workspace is well ventilated. This aids in not only dispersing the wood dust but also in keeping you refreshed during the process.

9. The Evolution of Sandpaper: Innovations to Look Out For

Like all industries, the world of sandpaper has seen its fair share of innovations. Nano-enhanced minerals are being incorporated into newer sandpapers to enhance longevity and efficiency. Some brands are venturing into creating multi-purpose sheets that can be used wet or dry, saving both time and money. Additionally, there’s been a rise in the production of ergonomically designed sanding tools, specially crafted to reduce hand fatigue. If you’re someone who spends a lot of time on woodworking projects, investing in these tools might be worthwhile.10. Beyond Wood: Sanding Other Materials

While our discussion has centred around wood, it’s worth noting that edge sanding isn’t limited to this material alone. Many of the principles we’ve discussed apply to sanding the edges of materials like acrylic, laminate, or even certain metals. The key lies in understanding the material’s properties and choosing sandpaper that aligns with them. Always test on a small patch before committing to the entire edge to ensure compatibility. Now, having immersed ourselves in the broader world of sanding, let’s draw our findings to a close.Conclusion

Edge sanding, while it may seem like a minor part of the crafting process, is indeed an art in its own right. Your choice of sandpaper plays a pivotal role in determining the quality of the finished product. A well-sanded edge speaks of dedication, passion, and craftsmanship. Remember, as with many things in life, the devil is in the details. Your woodwork might be the most beautifully designed, but if those edges aren’t up to snuff, it’ll always feel incomplete. So the next time you’re faced with the array of sandpapers at your local crafts shop, take a moment. Think of the edges and choose wisely. Thank you for joining me on this journey into the world of sandpaper. Here’s to edges that shine and craftsmanship that stands the test of time. Cheers!Some Useful Links:

- Stairs Sanding & Refinishing

- Floor Sanding Services

- School Floor Sanding

- Wood Floor Restorations

- Wood Floor Repairs

- Wood Floor Polishing

More from our Blog:

How to Achieve Professional Results with Edge Sanding The Importance of Edge Sanding in Floor Refinishing Hand Scraping for Parquet Floors: Enhancing the Beauty of Geometric Designs The Versatility of Hand Scraping Floors: From Modern to Traditional Design Sanding and Hand Scraping Combination Techniques for Custom Wood Floors Hand Scraping Techniques for Different Types of Hardwood Floors How to Hand Scrape Floors Safely and Effectively Hand Scraping Floors: Reviving Antique Wood for a Vintage Look The History and Evolution of Hand-Scraping Floors

Sanding

We provide virtually dust-free sanding with our continuous belt machinery with mobile extraction units, giving you a safer environment for your family.

Oiling

This organic finish not only adds beauty to your home but also has exceptional water-repellent characteristics, making it easier to clean and maintain.

Waxing

This natural floor finish offers the softest and most mellow appearance – and leaves your floor able to breath.

Buffing

Using soft buffing machines (and hand-polishing where required) will bring a wonderful sheen to your newly-finished floor.

Repairs

We offer a full assessment of your wooden floors to determine what repairs are needed to provide the perfect working surface for the later stages of sanding, staining and sealing.

Restoration

We offer a comprehensive restoration process designed to address floors that are improperly fitted or damaged over time through wear and tear.

Request a fixed price quote for your wood floor restoration now

Simply enter your postcode below to get started.

Services

Wood Floor Sanding Wood Floor Restoration Wood Floor Scratch Repair Squeaky Wood Floor Repair Parquet Floor Sanding Parquet Floor Restoration Commercial Floor Sanding Church Floor Sanding Community Centre Floor Sanding School Floor Sanding Gap Filling Gap Filling with ResinCopyright © Mr Sander®

Privacy & Cookies Terms & Conditions Complaints Procedure Cancellation Rights Sitemap