London:

Nationwide:

The Pros and Cons of Hand Sanding vs. Machine Sanding for Floors

Posted on January 15, 2024

Floor sanding techniques

Hand Sanding vs. Machine Sanding for Floor Restoration

When embarking upon the task of wood floor restoration, one is faced with a critical decision: to employ the traditional method of hand sanding or to embrace the technological advancements of machine sanding. This pivotal choice bears significant implications for the quality, duration, and overall experience of the floor refinishing process.

In the British tradition of craftsmanship, both techniques are steeped in history, each with its own set of proponents and detractors. Hand sanding, often regarded as the more artisanal approach, is celebrated for its precision and bespoke quality. Machine sanding, on the other hand, is lauded for its efficiency and uniform results.

This exploration will delve into the nuances of each method, providing a comprehensive comparison. Our aim is not to champion one method over the other, but rather to present a balanced view that enables homeowners and professionals alike to make an informed decision that best suits their specific needs and circumstances.

As we proceed, we shall consider various factors, including the quality of the finish, time efficiency, cost, physical exertion, and the suitability of each method for different types of flooring. By the end of this discussion, readers should have a clearer understanding of the pros and cons of hand sanding versus machine sanding, guiding them towards a decision that aligns with their wood floor restoration objectives.

What is Wood Floor Hand Sanding?

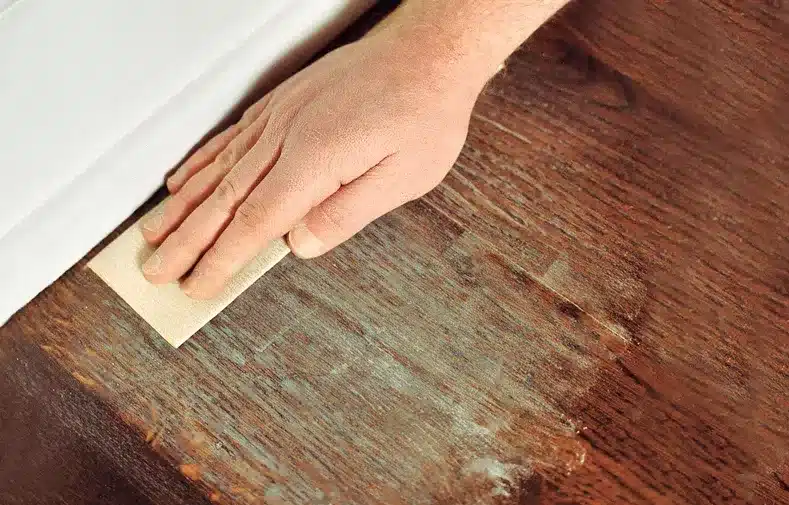

Wood floor hand sanding refers to the process of manually smoothing and finishing wooden floors using sandpaper or similar abrasive materials. Unlike machine sanding, which uses power tools such as drum sanders or orbital sanders, hand sanding is done by hand, offering greater control and precision. This method is often used for delicate work, such as:

- Detail Sanding: Hand sanding is ideal for reaching corners, edges, and other areas where a power sander might not fit or could damage the floor.

- Finishing Touches: After machine sanding, hand sanding is often used to give a final smooth finish, removing any marks or roughness left by the larger sanders.

- Refinishing Antique or Delicate Floors: For older or more delicate wood floors, hand sanding can be gentler and more appropriate than machine sanding.

- Sanding Intricate Patterns: In floors with intricate inlays or patterns, hand sanding allows for careful work around the details without damaging them.

Hand sanding is more labor-intensive and time-consuming than machine sanding, but it offers a level of detail and care that is sometimes necessary for certain flooring projects. It requires various grits of sandpaper, starting with a coarser grit for initial sanding and moving to finer grits for a smooth finish. The process is often followed by staining and sealing to protect the wood and enhance its appearance.

Pros of Wood Floor Hand Sanding:

- Precision and Control: Hand sanding allows for meticulous control over the sanding process, which is crucial for detailed work, especially around edges, corners, and intricate patterns.

- Gentler on Wood: It’s less aggressive than machine sanding, making it suitable for delicate, antique, or easily damaged wood floors.

- Reduced Risk of Damage: There’s a lower risk of accidentally gouging or unevenly sanding the floor, a common risk with powerful sanding machines.

- Accessibility in Tight Spaces: Hand sanding can reach areas where larger sanding machines can’t, ensuring a uniform finish across the entire floor.

- No Need for Heavy Machinery: It eliminates the need for renting or buying expensive sanding machines, which can be cost-effective for small projects.

Cons of Wood Floor Hand Sanding:

- Time-Consuming: It’s significantly slower than machine sanding, making it impractical for large areas or time-sensitive projects.

- Physically Demanding: Hand sanding requires a lot of manual effort and can be physically taxing, especially on the knees and back.

- Less Even Finish: Achieving a perfectly even finish is more challenging by hand, and it requires a skilled and steady approach.

- Dust Production: Like machine sanding, it produces dust, but without the benefit of the dust collection systems often found in sanding machines.

- Skill Dependent: The quality of the finish heavily depends on the skill and experience of the person doing the sanding, which can be a disadvantage for DIY projects.

In summary, while wood floor hand sanding offers greater precision and is gentler on delicate surfaces, it is labor-intensive and time-consuming, making it less suitable for large or less detailed projects.

What is Wood Floor Machine Sanding?

Wood floor machine sanding is a process used to smooth, prepare, and finish hardwood floors. It involves the use of specialized sanding machines, which can range from large, professional-grade drum sanders to smaller, more manageable orbital sanders. Here’s a general overview of the process:

- Preparation: Before sanding, the floor is cleaned to remove any dirt, debris, or old finish materials that might interfere with the sanding process.

- Coarse Sanding: The first step involves using a coarse-grit sandpaper to remove the old finish and level the floor. This is typically done with a heavy-duty sander like a drum sander.

- Intermediate Sanding: After the initial coarse sanding, a medium-grit sandpaper is used to further smooth the floor. This step helps to eliminate any scratches or imperfections left by the coarse sanding.

- Fine Sanding: The final sanding step uses fine-grit sandpaper to achieve a smooth, polished surface. This is often done with an orbital sander, which is less aggressive and allows for a finer finish.

- Edging: For areas that are hard to reach with large machines, such as corners and edges, a handheld edger is used. This ensures that the entire floor is uniformly sanded.

- Cleaning and Finishing: After sanding, the floor is thoroughly cleaned to remove all dust and debris. A finish, such as varnish, lacquer, or oil, is then applied to protect the wood and enhance its appearance.

Wood floor machine sanding is an important process in the renovation and maintenance of hardwood floors. It helps to restore old, worn-out floors and can significantly improve the aesthetic of a room. This process requires skill and care, as improper sanding can damage the wood. Therefore, it’s often recommended to seek professional help, especially for large or complex projects.

Pros of Machine Sanding

- Restores Floor Appearance: Machine sanding effectively removes old finishes, scratches, and stains, restoring the original beauty of the hardwood floor.

- Evens Out the Surface: It helps in leveling the floor, fixing any unevenness or warping that might have occurred over time.

- Prepares for Refinishing: Sanding is a necessary step before refinishing, allowing the new finish to adhere properly and evenly.

- Increases Home Value: Well-maintained and freshly sanded hardwood floors can increase the aesthetic appeal and value of a home.

- Longevity of Floors: Regular sanding and maintenance can extend the life of hardwood floors, preventing the need for more costly repairs or replacements.

- Customizable Finish: Sanding allows for customization in terms of the type of finish or stain applied afterward, offering versatility in home décor.

Cons of Machine Sanding

- Requires Skill and Experience: Improper sanding techniques can damage the floor, leading to uneven surfaces or even permanent damage to the wood.

- Dust and Debris: The process can generate a significant amount of dust, which can be a health hazard and requires thorough cleaning post-sanding.

- Noise and Disruption: Sanding machines are typically loud and can be disruptive, especially in residential settings.

- Cost: Professional sanding services can be expensive, and the cost of renting equipment adds up if doing it yourself.

- Time-Consuming: The process can be lengthy, especially for larger areas, and requires preparation and cleanup time.

- Limited Number of Sandings: Hardwood floors can only be sanded a limited number of times before the wood becomes too thin, which is a consideration for older floors.

In summary, while wood floor machine sanding can significantly improve the appearance and lifespan of hardwood floors, it requires expertise, creates disruption and dust, and involves costs that need to be considered.

Comparing hand and machine sanding

When it comes to floor restoration, choosing between hand and machine sanding is not just a matter of preference but a strategic decision based on several critical factors. This comparison aims to illuminate the key differences and help you make an informed choice.

1. Efficiency

In terms of efficiency, machine-sanding is the clear winner. It covers large areas rapidly, making it ideal for bigger projects or when time is a constraint. Hand sanding, while meticulous, is significantly slower and more suited to smaller, more detailed tasks.

2. Finish Quality

The quality of the finish can vary depending on the method used. Machine sanding provides a uniform finish, essential for a professional look, especially over large surface areas. Hand sanding, on the other hand, allows for a level of detail and customisation that machines cannot match, making it ideal for antique restoration or detailed work.

3. Cost Implications

Cost implications are also a factor. Hand sanding requires minimal investment in tools, making it more cost-effective for small projects or occasional use. Machine sanding, while more expensive initially due to the cost of the machine, can be more economical in the long run for frequent use or large-scale projects due to its efficiency.

4. Situational Considerations

The choice also depends on the specific situation. For intricate patterns or delicate floors, hand sanding may be the safer option to avoid damage. Conversely, for large, flat areas or when working with harder wood types, machine sanding is generally more effective.

5. Safety and Environmental Aspects

Safety and environmental considerations are crucial. Machine sanding, with its advanced dust extraction systems, is generally safer and cleaner, reducing the risk of respiratory issues. Hand sanding, while less noisy, can generate significant dust without proper dust management techniques.

Situational Considerations

When determining whether to opt for hand sanding or machine sanding, several situational factors play a pivotal role. Understanding these considerations is essential for making a choice that aligns with both the practical requirements of the project and the desired outcome.

1. Types of Wood and Floor Condition

The type of wood and the condition of the floor are critical factors. Softer woods or floors with intricate designs might benefit from the gentle touch of hand sanding to avoid damage. Conversely, harder woods or floors in poor condition might necessitate the efficiency and power of a machine sander.

2. Scale of the Project

The scale of the project is another important consideration. For large-scale projects, such as commercial spaces or entire households, machine sanding offers a time-efficient solution. For smaller projects, like a single room or touch-up work, hand sanding can be more practical and economical.

3. Level of Detail Required

If the project requires working around detailed inlays, edges, or corners, hand sanding provides the precision needed. Machine sanders, while efficient, may struggle to navigate these intricate areas without risking damage.

4. Availability of Resources

The availability of resources, including time, budget, and equipment, also influences the decision. Hand sanding is less costly in terms of equipment but more demanding in terms of time and labour. Machine sanding, while initially more expensive due to the cost of the equipment, can save time and labour costs in the long run.

5. DIY Skill Level

The skill level of the person undertaking the project is significant. Hand sanding is more forgiving for beginners, while machine sanding requires a certain level of expertise to avoid mistakes that could be costly or difficult to rectify.

6. Health and Safety Concerns

Lastly, health and safety concerns should be taken into account. Machine sanding, with its advanced dust extraction, is generally safer for respiratory health. However, it also requires knowledge of proper safety practices to prevent accidents. Hand sanding is less hazardous in terms of machinery operation but requires diligent dust management.

Safety and environmental aspects

Safety and environmental considerations are paramount in the process of floor sanding, whether opting for hand or machine sanding. Each method carries its own set of risks and environmental impacts, which should be carefully weighed.

1. Dust Generation and Inhalation

One of the primary concerns in floor sanding is the generation of dust. This dust can pose serious health risks if inhaled, potentially causing respiratory issues. Machine sanding often comes with advanced dust extraction systems that significantly reduce the amount of airborne dust. Hand sanding, while generating less dust at a time, can still lead to accumulation if not properly managed. Wearing appropriate dust masks and ensuring good ventilation are crucial in both methods.

2. Noise Pollution

Machine sanding can be quite loud, contributing to noise pollution. This factor is especially important in residential areas or enclosed spaces. Hand sanding is much quieter and is preferable in environments where noise is a concern.

3. Physical Strain and Ergonomics

Hand sanding requires a considerable amount of physical effort and can be strenuous over long periods of time. This can lead to muscle fatigue or strain. Proper ergonomics and taking regular breaks are important. Machine sanding, while less physically demanding, requires careful handling to avoid accidents due to the machine’s power and movement.

4. Environmental Impact of Equipment

The environmental impact of producing and disposing of sanding equipment is also a consideration. Machine sanders require electricity and are made from materials that have a higher environmental footprint in terms of manufacturing and disposal. Hand tools are generally simpler, have a longer lifespan, and are less impactful in terms of resource consumption.

5. Safe Disposal of Waste

The disposal of sanding waste (sawdust) must be handled responsibly. Sawdust from treated woods can contain harmful chemicals and should not be disposed of in a way that harms the environment. Proper collection and disposal methods should be implemented, regardless of the sanding method used.

6. Use of Sustainable Materials

Finally, considering the sustainability of the materials used (like sandpaper) is important. Opting for products made from recycled or eco-friendly materials can reduce the overall environmental impact of the sanding project.

Conclusion

The debate between hand sanding and machine sanding is one that encompasses a range of factors, each pivotal in its own right. This exploration has illuminated the strengths and weaknesses of both methods, presenting a comprehensive picture to aid in informed decision-making.

Hand sanding, with its precision and bespoke quality, remains a cherished technique in situations demanding meticulous attention to detail, especially in the realm of heritage restoration or delicate work. Its main challenges lie in the physical exertion required and the time-intensive nature of the process.

Machine sanding, on the other hand, stands as a testament to the advancements in modern technology, offering efficiency and consistency that hand sanding struggles to match. Ideal for large-scale projects or scenarios where time is a critical factor, it does, however, require a significant initial investment and a certain level of skill to operate effectively.

In conclusion, the choice between hand and machine sanding for wood floors should be guided by a careful assessment of the project’s scope, the type of floor, desired finish quality, available resources, and environmental and safety considerations. Neither method is universally superior; rather, each has its own set of circumstances where it excels. By understanding and respecting the nuances of each approach, one can ensure a floor restoration process that is not only effective but also aligns with the specific needs and values of the task at hand.

Sanding

We provide virtually dust-free sanding with our continuous belt machinery with mobile extraction units, giving you a safer environment for your family.

Oiling

This organic finish not only adds beauty to your home but also has exceptional water-repellent characteristics, making it easier to clean and maintain.

Waxing

This natural floor finish offers the softest and most mellow appearance – and leaves your floor able to breath.

Buffing

Using soft buffing machines (and hand-polishing where required) will bring a wonderful sheen to your newly-finished floor.

Repairs

We offer a full assessment of your wooden floors to determine what repairs are needed to provide the perfect working surface for the later stages of sanding, staining and sealing.

Restoration

We offer a comprehensive restoration process designed to address floors that are improperly fitted or damaged over time through wear and tear.

Request a fixed price quote for your wood floor restoration now

Simply enter your postcode below to get started.

Services

Wood Floor Sanding Wood Floor Restoration Wood Floor Scratch Repair Squeaky Wood Floor Repair Parquet Floor Sanding Parquet Floor Restoration Commercial Floor Sanding Church Floor Sanding Community Centre Floor Sanding School Floor Sanding Gap Filling Gap Filling with ResinCopyright © Mr Sander®

Privacy & Cookies Terms & Conditions Complaints Procedure Cancellation Rights Sitemap