London:

Nationwide:

Hand Sanding vs. Machine Sanding: Which is better for Floor Restoration

Posted on January 9, 2024

Floor sanding techniques

Hand Sanding vs. Machine Sanding: The Ultimate Guide for Floor Restoration

In the refined world of floor restoration, the choice between hand sanding and machine sanding stands as a topic of considerable debate. This discussion is particularly vital for those seeking to preserve the charm of their wooden floors while ensuring a finish of the highest quality. The decision not only affects the outcome but also speaks volumes about one’s approach to craftsmanship and care for the environment.

Hand sanding, often viewed as a traditional art, is revered for its precision and the personal touch it brings to each project. It’s a method steeped in heritage, demanding a level of skill and patience that is reminiscent of a bygone era of meticulous craftsmanship. Conversely, machine sanding represents the modern approach, blending efficiency with innovation to deliver results in a fraction of the time.

This comparative exploration delves into the nuances of both techniques. We aim to provide an insightful guide for homeowners, DIY enthusiasts, and professionals alike seeking to make an informed choice between these two methods for their hand sanding projects. From the quality of finish to cost implications, environmental impact, and suitability for different types of floors, we shall traverse the entire landscape of floor sanding.

As we embark on this journey, it’s essential to remember that the choice between hand and machine sanding isn’t just a matter of technique. It’s a reflection of one’s values, the importance placed on tradition versus modernity, and a commitment to quality and sustainability. So, let us delve into the world of hand sanding, where each stroke and sweep holds the potential to transform the mundane into the magnificent.

Understanding the Basics of Floor Sanding

What is hand sanding?

Hand sanding is a method steeped in tradition, requiring a meticulous approach. It involves manually rubbing the sandpaper against the floor surface. This technique allows for a high degree of control and enables the sander to reach into nooks and crannies that machines might miss. Hand sanding is often preferred for delicate tasks where precision is paramount. The process is slow and labour-intensive but offers the satisfaction of a job done with personal touch and attention to detail.

What is machine sanding?

Machine sanding, on the other hand, is a more modern approach that employs the use of electric sanders. These machines range from large belt sanders to smaller orbital models. The primary advantage of machine-sanding is its efficiency. It’s significantly faster than hand-sanding and requires less physical effort. Machine sanders are particularly effective for larger floor areas, providing a consistent finish over expansive surfaces. However, they may not be as effective at handling intricate work or getting into tight spaces.

The Fundamentals of Sanding Floors

Regardless of the method chosen, the fundamental goal of floor sanding is to remove the old finish, level the surface, and prepare it for a new finish. This involves several steps:

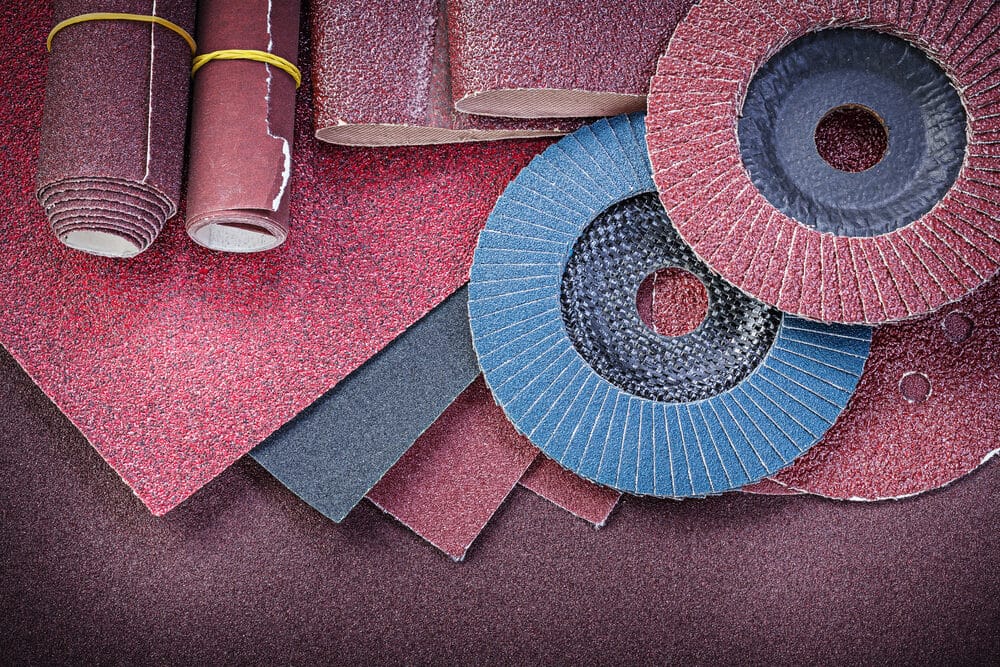

Choosing the Right Grit:

Sandpaper comes in various grits. Lower numbers indicate a rougher grit, suitable for initial sanding stages. Higher numbers denote finer grits, used for finishing touches.

Sequential Sanding:

Sanding should be done in a sequence, starting with a rough grit and gradually moving to finer grits. This ensures the removal of deep scratches and results in a smooth finish.

Dust Management:

Sanding generates a significant amount of dust. Proper dust management is crucial, especially when machine sanding, to maintain a clean working environment and reduce health risks.

Edge Sanding:

This is crucial for a uniform look, as edges often require special attention. Hand sanding is typically used for edges and corners where machines can’t reach.

By understanding these basics, one can appreciate the nuances of both hand and machine sanding, setting the stage for a more detailed exploration of their respective pros and cons.

The Pros and Cons of Hand Sanding

Advantages of Hand Sanding

- Precision and Control: Hand sanding allows for meticulous control over the sanding process. It’s ideal for working on intricate designs and getting into hard-to-reach areas where a machine might not fit or could cause damage.

- Gentler on Wood: This method is typically gentler on floors, reducing the risk of removing too much material or causing unintended damage to the wood’s surface.

- Less Noise and Dust: Hand sanding is quieter compared to its machine counterpart and generally produces less dust, making it more suitable for environments where noise and dust control are essential.

- No Need for Power Tools: It doesn’t require expensive machinery or electricity, making it accessible to anyone with basic tools.

- Craftsmanship and Satisfaction: There’s a certain charm and sense of accomplishment in doing the job by hand, preserving traditional craftsmanship skills.

Disadvantages of Hand Sanding

- Time-Consuming: The most significant drawback of hand sanding is that it’s considerably more time-consuming, making it less practical for larger projects or in time-sensitive situations.

- Physically demanding: It requires a lot of manual effort and can be physically taxing, especially for larger areas or prolonged tasks.

- Inconsistency: Achieving a uniformly sanded surface can be challenging, particularly for less experienced individuals.

- Limited Efficiency: For very rough or damaged floors, hand sanding might not be the most efficient method to remove deep scratches or level the floor.

- Skill-dependent: The quality of the outcome heavily relies on the skill and experience of the person doing the sanding.

The Benefits and Drawbacks of Machine Sanding

Advantages of Machine Sanding

- Efficiency and Speed: Machine sanding is significantly faster than hand sanding. It’s highly efficient for large areas, reducing the time and effort required to complete a project.

- Consistency: Machines provide a consistent level of sanding across the floor. They are especially effective in maintaining uniformity in the sanding process, which is crucial for professional-looking finishes.

- Reduced Physical Effort: Unlike hand sanding, machine sanding requires less physical exertion, making it a more comfortable option for extended use or larger projects.

- Effective for Tough Jobs: Machine sanders are powerful and can easily handle rough surfaces and remove old finishes more effectively than hand sanding.

- Advanced Technology: Modern sanding machines often come with dust extraction systems, reducing the mess typically associated with sanding and improving the working environment.

Disadvantages of Machine Sanding

- Risk of Damage: If not used carefully, machine sanders can quickly remove too much material, leading to damages like gouges in the wood, which are difficult to repair.

- Limited Accessibility: Machines can be bulky and may not reach corners or edges effectively, often necessitating hand sanding for these areas.

- Noise and Dust Production: Despite advancements in technology, machine sanding is generally noisier and produces more dust compared to hand sanding.

- Cost: The cost of purchasing or renting sanding machines can be a significant investment, particularly for high-quality or industrial-grade equipment.

- Skill Requirement: While less physically demanding, operating a sanding machine efficiently still requires skill and experience to avoid mistakes and achieve a high-quality finish.

In essence, machine sanding stands out for its efficiency and ability to handle large and tough sanding jobs with ease. However, this comes with the trade-off of higher costs, potential risks of damage, and the need for additional hand sanding in inaccessible areas. The choice between machine and hand sanding will depend on the specific requirements of the floor, the desired quality of finish, and the resources available for the task.

Comparing Quality of Finish

When it comes to the quality of finish achieved by hand sanding versus machine sanding, several key factors come into play. The choice between these two methods can significantly impact the final appearance and durability of the floor.

Hand Sanding Finish Quality:

- Smoothness and Attention to Detail: Hand sanding offers unparalleled precision, allowing for a smooth finish, especially in intricate areas and along edges. The manual control ensures that even the smallest imperfections can be addressed, resulting in a highly polished look.

- Customisation: Hand sanding allows for a more customised approach. The sander can adjust the pressure and motion based on the wood grain and condition, leading to a finish that is in harmony with the natural character of the wood.

- Gentleness on Wood: The gentle approach of hand sanding preserves the integrity of the wood, making it ideal for antique or delicate floors where preserving the wood’s character is crucial.

Machine Sanding Finish Quality:

- Uniformity and Consistency: Machine sanding provides a more uniform and consistent finish over large areas. This is particularly important for contemporary floors where a sleek, even look is desired.

- Effectiveness on Hard Surfaces: For harder wood species or floors with significant damage or wear, machines are more effective in levelling the surface and preparing it for refinishing.

- Speed and Efficiency: While speed doesn’t directly affect finish quality, the efficiency of machine sanding means less time is spent on the sanding process, which can be beneficial in a commercial context or when working under time constraints.

Comparative Analysis:

- Skill Level: The quality of the finish with both methods heavily depends on the skill and experience of the person doing the sanding. A skilled craftsman can achieve excellent results with either method.

- Type of Project: For intricate, artisanal projects or the restoration of antique flooring, hand sanding might be preferable. For modern, large-scale projects, machine sanding is likely more suitable.

- Final Application: The choice may also depend on the type of finish being applied afterward. Some finishes might benefit from the slightly more textured surface that machine sanding produces, while others might need the ultra-smooth surface that hand sanding offers.

Considerations for Different Floor Types

When deciding between hand sanding and machine sanding, the type of floor plays a crucial role. Different materials and floor conditions require distinct approaches for optimal results. Here’s a breakdown of the considerations for various floor types:

Hardwood Floors:

- Old or Delicate Hardwood: For antique hardwood floors or those with intricate patterns (like parquet), hand sanding is often preferable to preserve the detail and integrity of the wood.

- New or Robust Hardwood: Modern, robust hardwood floors can benefit from machine sanding, especially for initial rough sanding, as it’s efficient and effective in smoothing out imperfections.

Softwood Floors:

- Vulnerability to Damage: Softwoods are more susceptible to damage. Hand sanding allows for a gentler approach, reducing the risk of gouging or excessive wear.

- Finish Quality: For a finer finish on softwood, hand sanding might be necessary, at least as a final step, to achieve a smooth, even surface.

Engineered Wood Floors:

- Limited Sanding Layer: Engineered wood typically has a thin veneer of real wood. Careful hand sanding is advisable to avoid sanding through this layer.

- Use of Machines: If using a machine, a gentle approach with fine-grit sandpaper and an experienced hand are essential.

Parquet and Patterned Floors:

- Directional Sanding: These floors require sanding in multiple directions due to the varied grain pattern. Hand-sanding offers the precision needed for such complex tasks.

- Machine Sanding Challenges: Machine sanding can be challenging due to the cross-grain of the patterns, potentially leading to scratches or uneven wear.

Cork Floors:

- Soft and delicate nature: Cork is a softer material that can easily be damaged by aggressive sanding. Hand sanding is often recommended for cork floors.

- Light Machine Sanding: If machine sanding is used, it should be done lightly with fine-grit sandpaper and by someone skilled in sanding cork.

Bamboo Floors:

- Hardness Variability: Bamboo varies in hardness. Strand-woven bamboo is quite hard and might handle machine sanding well, while traditional bamboo might be better suited to hand sanding.

- Careful Sanding Required: Regardless of the method, sanding bamboo requires care due to its tendency to splinter.

Reclaimed or distressed floors:

- Preserving Character: Hand sanding is often ideal for maintaining the unique character and patina of reclaimed wood floors sanding.

- Light Machine Sanding: If the goal is to smooth out rougher areas without losing the distressed look, light machine sanding with a fine grit can be effective.

General Considerations:

- Condition of the Floor: Assess the floor’s condition. Floors with extensive damage, deep scratches, or warping might initially need the efficiency of machine sanding.

- Final Appearance: Consider the desired final appearance. A rustic look might allow for a more aggressive sanding method, while a refined finish would require a delicate approach.

Cost Comparison: Hand Sanding vs. Machine Sanding

The cost of sanding can vary significantly based on several factors, including the size of the area, the condition of the floor, and the chosen method of sanding. Here’s a comparison of the costs associated with hand sanding versus machine sanding:

Hand sanding costs:

- Materials: The cost of sandpaper and hand sanding tools is relatively low. However, different grits of sandpaper may be needed for different stages of the job.

- Labour: Hand sanding is labour-intensive and time-consuming. If hiring a professional, the cost can be higher due to the longer hours required to complete the project.

- Efficiency: For large areas, the time and effort involved in hand sanding can significantly increase the overall cost, making it less economical for bigger projects.

Machine Sanding Costs:

- Equipment Rental or Purchase: Renting a floor sander is a common approach and can be cost-effective for short-term projects. The rental cost varies depending on the type of sander and the rental duration. Purchasing a machine has a higher upfront cost and is more suitable for professionals or those with frequent sanding needs.

- Materials: Besides renting or buying the machine, you’ll need to purchase sanding discs or belts, which can vary in price based on grit and quality.

- Labour: Machine sanding is faster, which can reduce the overall labour cost, especially if paying for professional services. This makes machine-sanding more cost-effective for larger areas.

- Skill Level: Hiring a skilled professional for machine sanding may cost more per hour compared to hand sanding, but the job is completed in a shorter time frame.

Ultimately, the choice between hand sanding and machine sanding will depend not only on the cost but also on the specific requirements of the project, the desired quality of finish, and personal preferences in terms of time investment and effort.

Environmental Impact and Safety Considerations

When considering the environmental impact and safety aspects of hand sanding versus machine sanding, it’s important to evaluate both methods in terms of their ecological footprint and the health and safety implications for those undertaking the work.

Environmental Impact:

- Dust Production:

- Hand sanding produces less dust compared to machine sanding, resulting in a lower impact on indoor air quality and a reduced need for dust extraction systems.

- Machine sanding generates a significant amount of dust. While modern sanding machines often come with dust collection systems, there is still a higher environmental burden due to the increased dust production and energy usage.

- Energy Usage:

- Hand Sanding: There is virtually no energy usage apart from human effort, making it more environmentally friendly.

- Machine Sanding: Requires electricity to operate the sanding machines, contributing to energy consumption and associated environmental impacts.

- Noise Pollution:

- Hand sanding produces minimal noise, thus having a negligible impact on noise pollution.

- Machine sanding can be quite noisy, contributing to noise pollution, which is an environmental concern, especially in residential areas or where noise regulations are in place.

Safety Considerations:

- Respiratory Health:

- Both hand and machine sanding produce dust particles that can be harmful if inhaled. Wearing a dust mask or respirator is essential, regardless of the method used.

- Machine sanding, especially without proper dust extraction, poses a higher risk for respiratory issues due to the larger volume of dust.

- Physical Strain and Injury Risk:

- Hand sanding can be physically demanding and may lead to strain or repetitive motion injuries, especially in larger projects. Proper technique and frequent breaks are important.

- Machine sanding reduces physical strain but carries risks of injury from the machinery. Proper handling, understanding of the equipment, and use of safety gear (like eye protection and hearing protection) are crucial.

- Chemical Exposure:

- In both methods, if the sanding is part of a larger refinishing project, there might be exposure to chemicals in varnishes or stains. Adequate ventilation and protective equipment are important to minimise health risks.

- Ergonomics:

- Hand sanding requires attention to ergonomic practices to avoid strain.

- Machine sanding, while less physically demanding, still requires attention to posture and handling to prevent discomfort or injury.

The Verdict: Which Method Suits Your Needs?

Deciding between hand sanding and machine sanding for your floor project depends on various factors, including the scale of the project, the type of floor, the desired finish, cost considerations, environmental impact, and personal preferences. Here’s a summary to help you make an informed decision:

Project Scale and Time Constraints:

- Hand sanding is ideal for smaller projects, intricate work, or when time is not a pressing factor.

- Machine sanding is more suitable for larger areas or when a quick turnaround is required.

Type of Floor:

- Hand sanding is better for delicate, antique, or detailed floors (like parquet) where preserving detail and minimising damage are key.

- Machine Sanding: Effective for robust, modern hardwood floors, especially those requiring significant levelling or repair.

Desired Quality of Finish:

- Hand sanding offers a high degree of control for a meticulous, customised finish, ideal for high-end refurbishments.

- Machine sanding provides a consistent, uniform finish suitable for contemporary floor styles.

Cost Implications:

- Hand sanding can be more expensive in terms of labour for large areas but has lower equipment costs.

- Machine sanding has higher equipment costs but can be more cost-effective in terms of labour for larger projects.

Environmental and Safety Considerations:

- Hand sanding has less environmental impact and lower noise levels, but is physically more demanding.

- Machine Sanding: higher dust and noise production, requiring effective dust extraction and safety measures.

Personal preference and skill level:

- Hand sanding requires more skill and patience but can be more satisfying for those who appreciate traditional craftsmanship.

- Machine sanding requires an understanding of machinery and is less physically demanding, making it a pragmatic choice for many.

Conclusion

The debate between hand sanding and machine sanding for restoration is not just a matter of technique but a reflection of various factors, including project requirements, floor type, desired outcome, and personal values. While hand sanding offers the benefits of precision, control, and a gentler touch suitable for detailed and delicate work, it is labour-intensive and time-consuming. Machine sanding, on the other hand, stands out for its efficiency and consistency, making it particularly beneficial for large-scale projects or floors requiring significant levelling.

The choice between these two methods should be informed by a thorough consideration of the project’s scale, the specific characteristics of the floor, the desired quality of finish, cost implications, environmental impact, safety considerations, and personal preference. Each method has its own unique advantages and drawbacks, and often, a combination of both hand sanding and machine sanding provides the most effective approach, balancing efficiency with attention to detail.

Ultimately, the decision on which method to use for sanding should align with the individual’s goals and resources, ensuring that the final result not only enhances the beauty and longevity of the floor but also aligns with the sander’s craftsmanship and environmental ethos. Whether you choose hand sanding for its traditional charm or machine sanding for its modern efficiency, the key lies in executing the method with care, precision, and an understanding of the material you are working with.

Sanding

We provide virtually dust-free sanding with our continuous belt machinery with mobile extraction units, giving you a safer environment for your family.

Oiling

This organic finish not only adds beauty to your home but also has exceptional water-repellent characteristics, making it easier to clean and maintain.

Waxing

This natural floor finish offers the softest and most mellow appearance – and leaves your floor able to breath.

Buffing

Using soft buffing machines (and hand-polishing where required) will bring a wonderful sheen to your newly-finished floor.

Repairs

We offer a full assessment of your wooden floors to determine what repairs are needed to provide the perfect working surface for the later stages of sanding, staining and sealing.

Restoration

We offer a comprehensive restoration process designed to address floors that are improperly fitted or damaged over time through wear and tear.

Request a fixed price quote for your wood floor restoration now

Simply enter your postcode below to get started.

Services

Wood Floor Sanding Wood Floor Restoration Wood Floor Scratch Repair Squeaky Wood Floor Repair Parquet Floor Sanding Parquet Floor Restoration Commercial Floor Sanding Church Floor Sanding Community Centre Floor Sanding School Floor Sanding Gap Filling Gap Filling with ResinCopyright © Mr Sander®

Privacy & Cookies Terms & Conditions Complaints Procedure Cancellation Rights Sitemap