London:

Nationwide:

How to Use Edge Sanding to Create a Uniform Surface

Posted on September 9, 2023

Edge sanding

Unravelling the Mastery of Edge Sanding: Crafting a Seamless Surface from the Ground Up

The world of woodworking is one that thrives on precision, technique, and an unwavering attention to detail. In the pursuit of perfection, the act of edge sanding emerges as an essential skill, almost an art form in itself, aimed at achieving a uniform and flawless surface. This comprehensive guide, steeped in the rich tradition of British craftsmanship, seeks to illuminate the meticulous process of employing edge sanding to create a seamless surface that speaks volumes about quality and finesse. As we embark on this in-depth exploration, it becomes our prerogative to arm ourselves with a wealth of knowledge and practical insight that can help both seasoned craftsmen and budding enthusiasts reach the zenith of woodworking mastery. Let us journey through the annals of craftsmanship as we unveil the secrets behind achieving a uniform surface through the art of edge sanding.

Chapter 1: Laying a Solid Foundation: Understanding Your Tools and Materials

Before venturing further, understanding your materials and tools is the cornerstone of successful edge sanding. Here, we’ll unravel the various aspects that warrant consideration.

The choice of wood

First and foremost, choosing the right wood forms the crux of the endeavour. Different woods, from the sturdiness of oak to the pliability of pine, offer distinct characteristics that influence the sanding process, determining the outcome of your efforts.The Arsenal of Sandpapers

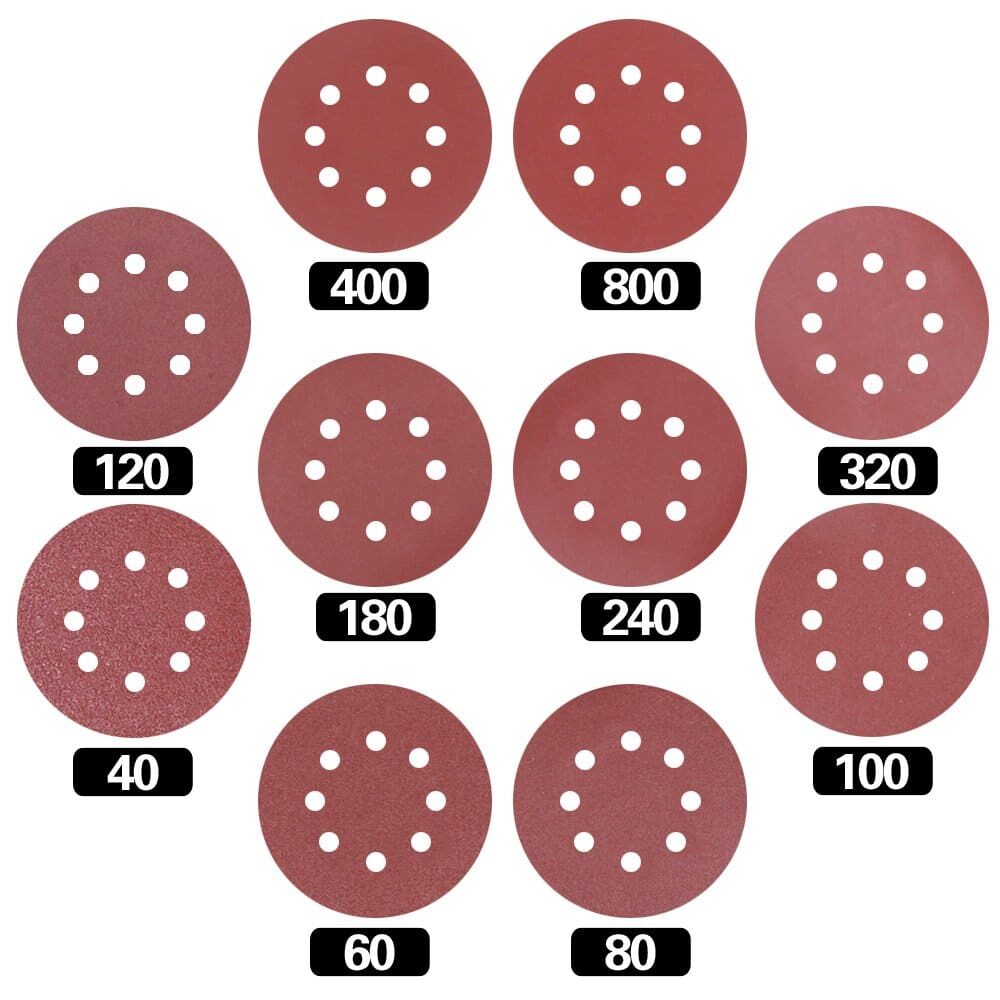

Equally vital is the choice of sandpaper. Ranging from coarse to fine grits, each variety serves a particular purpose, working in tandem to achieve a progressively smoother surface.

Chapter 2: The Preparatory Phase: Setting the Stage for Success

As any skilled craftsman would affirm, laying a strong foundation is quintessential. This chapter delves into the preparatory steps vital to setting the stage for a successful sanding process.Cleaning and inspection

Before you begin, ensure the wood is clean and free from foreign materials. A thorough inspection to identify and rectify any imperfections, such as knots and splinters, is also a critical initial step.Marking and measurement

Taking precise measurements and marking your wood judiciously can save you from many mishaps later in the process. This step ensures that the edge sanding process adheres to the desired dimensions and specifications.

Chapter 3: The Procedural Masterstroke: The Edge Sanding Process Unveiled

With firmly established groundwork, we now venture into the heart of the matter: the edge sanding process. Here, we break down each step meticulously to guide you towards achieving that coveted uniform surface.Beginning with Coarse Grit

The initial phase involves using coarse-grit sandpaper to remove substantial irregularities and shape the wood. This stage sets the tone, paving the way for finer grits to work their magic.Progressing to Medium Grit

Following the coarse grit, a medium-grit sandpaper takes over, refining the surface further and smoothing out the roughness left behind by its predecessor.The Finishing Touch with Fine Grit

Lastly, the fine-grit sandpaper steps in to add the final touches, refining the wood to a smooth, uniform surface. This stage embodies the very essence of finesse, bringing forth a surface that is nothing short of perfection.

Chapter 4: The Finer Nuances: Techniques and Tips for Mastery

As we delve deeper, understanding the finer nuances becomes paramount. This chapter offers a glimpse into the techniques and tips that can propel you towards mastery in edge sanding.The art of pressure

Learning to apply the right amount of pressure is crucial. Too much pressure can cause unwanted indentations, while too little might not yield the desired results.Directional Wisdom

Understanding the grain direction of the wood and moving your sandpaper accordingly can prevent unsightly scratches and enhance the uniformity of the surface.Keeping the sandpaper clean

Ensuring that your sandpaper is clean and free from accumulated residue guarantees a smoother sanding process, contributing to a more uniform surface.

Chapter 5: Preservation and Finishing: The Grand Finale

As we reach the crescendo, preservation and finishing become the focal points. Here, we explore how to protect and enhance the surface achieved through meticulous edge sanding.Choosing the right finish

Depending on the type of wood and the intended use of the piece, choosing the right finish can accentuate the beauty and longevity of your project.Application of the Finish

The application process of the finish, be it varnish, lacquer, or oil, requires a steady hand and a keen eye to avoid streaks and ensure an even coat.

Chapter 6: The Revel in Mastery: Celebrating Your Craft

As we stand at the conclusion of our journey, it is time to step back and appreciate the beauty and uniformity achieved through diligent edge sanding. This chapter encourages you to revel in your mastery and celebrate the artistry embodied in woodworking.Documentation and reflection

Keeping a record of your process and noting down insights and learnings can be a rich source of reflection and growth in your woodworking journey.Showcasing your work

Do not shy away from showcasing your work. Be it in a gallery, a blog, or social media, let the world witness the beauty that can be achieved through skilled edge sanding.Conclusion

As we draw the curtains on this comprehensive discourse, it is evident that the act of edge sanding is more than just a skill; it is a fine art that demands dedication, precision, and a deep understanding of the woodworking craft. Through meticulous preparation, a deep understanding of the materials and tools at hand, and a mastery of technique, one can indeed achieve a uniform surface that stands as a testament to quality craftsmanship. In embracing the rich British heritage of woodworking, let us continually aspire to hone our skills and create works of art that resonate with beauty and functionality. Let us forge forward, united in our quest for perfection, celebrating the glorious tradition of woodworking, where edge sanding stands as a beacon of excellence, guiding us towards the creation of pieces that are both timeless and exquisite. Thus, we invite you to immerse yourself in this fulfilling journey, to explore the depths of craftsmanship, and to witness firsthand the transformative power of edge sanding in crafting a seamless, uniform surface. Armed with knowledge and insight, may you forge a path of mastery, embodying the spirit of excellence and artistry that is the hallmark of British woodworking craftsmanship. In the world of woodworking, where every detail matters, may your journey be filled with discoveries, mastery, and an unyielding pursuit of perfection. Through the art of edge sanding, may you craft surfaces that are not only uniform but also embody the beauty and intricacies of the wood itself, creating pieces that stand as an ode to skill, dedication, and a deep-rooted love for the craft.Some Useful Links:

- Stairs Sanding & Refinishing

- Floor Sanding Services

- School Floor Sanding

- Wood Floor Restorations

- Wood Floor Repairs

- Wood Floor Polishing

More from our Blog:

The Importance of Consistent Pressure When Edge Sanding When to Use Edge Sanding vs. Hand Sanding Using Edge Sanding to Repair Scratches and Gouges How to Achieve Smooth Transitions with Edge Sanding How to Use Edge Sanding to Remove Stains and Discoloration The Effects of Edge Sanding on Different Wood Types Choosing the Right Edge Sanding Tool for Your Project Tips for Edge Sanding Wide Plank Flooring

Sanding

We provide virtually dust-free sanding with our continuous belt machinery with mobile extraction units, giving you a safer environment for your family.

Oiling

This organic finish not only adds beauty to your home but also has exceptional water-repellent characteristics, making it easier to clean and maintain.

Waxing

This natural floor finish offers the softest and most mellow appearance – and leaves your floor able to breath.

Buffing

Using soft buffing machines (and hand-polishing where required) will bring a wonderful sheen to your newly-finished floor.

Repairs

We offer a full assessment of your wooden floors to determine what repairs are needed to provide the perfect working surface for the later stages of sanding, staining and sealing.

Restoration

We offer a comprehensive restoration process designed to address floors that are improperly fitted or damaged over time through wear and tear.

Request a fixed price quote for your wood floor restoration now

Simply enter your postcode below to get started.

Services

Wood Floor Sanding Wood Floor Restoration Wood Floor Scratch Repair Squeaky Wood Floor Repair Parquet Floor Sanding Parquet Floor Restoration Commercial Floor Sanding Church Floor Sanding Community Centre Floor Sanding School Floor Sanding Gap Filling Gap Filling with ResinCopyright © Mr Sander®

Privacy & Cookies Terms & Conditions Complaints Procedure Cancellation Rights Sitemap