London:

Nationwide:

The Benefits of Hand Sanding for Finishing Floors

Posted on January 16, 2024

Floor sanding techniques

The Timeless Art of Hand Sanding for Floor Finishing

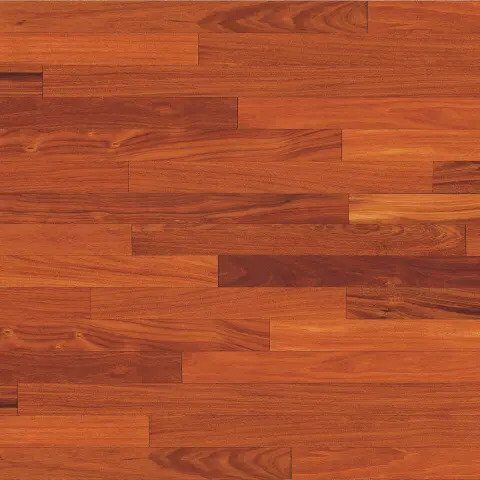

In the realm of floor finishing, the allure and enduring charm of wooden floors have captivated homeowners for generations. Amidst the evolving landscape of floor finishing techniques, one time-honoured method, often overshadowed by the roar of modern machinery, is hand sanding. This traditional approach, rooted deeply in craftsmanship and meticulous attention, offers an unspoken elegance and quality that transcends the mere functional aspects of floor finishing.

Hand sanding, a technique as old as the floors it refines, embodies a profound respect for the material at hand. It is a testament to the belief that true beauty in woodwork emerges from a harmonious blend of patience, skill, and a deep understanding of the wood’s nature. In this age where speed and efficiency are often paramount, hand sanding stands as a beacon of the artisan’s ethos, highlighting the virtues of precision, customisation, and a gentle touch.

As we embark on an exploration of hand sanding’s myriad benefits, it is essential to appreciate this method not merely as a means to an end but as a journey that honours the timeless beauty of wooden floors. The following sections will delve into the distinctive advantages of hand sanding, contrast its unique qualities with modern sanding methods, and provide insights into the tools and techniques that elevate this craft to an art form.

The Art of Hand Sanding

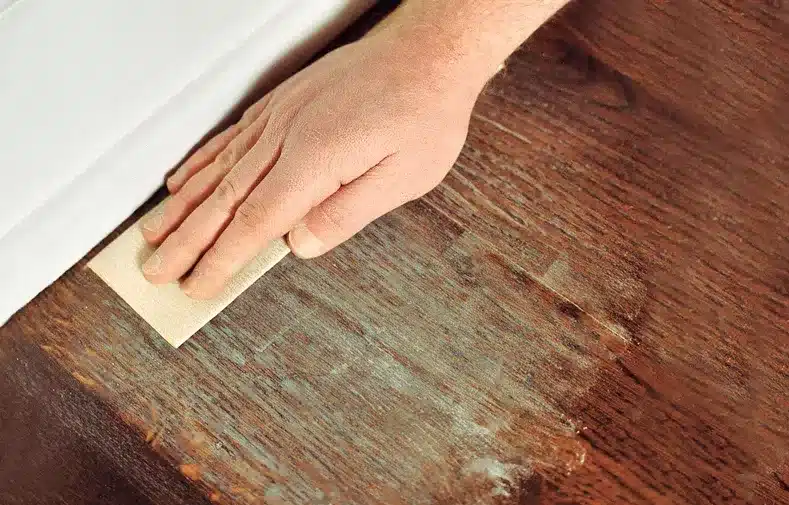

The art of hand sanding is a testament to the time-honoured traditions of floor finishing, where each movement of the sandpaper over the wood is not just a step in the process but a stroke of craftsmanship. Unlike mechanical sanding, hand sanding is an intimate, tactile practice that forms a deep connection between the artisan and the material.

At the heart of hand sanding lies the principle of understanding the wood’s grain, texture, and nuances. Each piece of timber has its own unique character, and hand-sanding allows the artisan to tailor their approach to these individual traits. It’s a method that requires not just skill but also an intuitive sense of the wood’s behavior. The craftsman’s hand can feel the subtle changes in texture, enabling them to adapt their technique in real-time to achieve a finish that machines can rarely replicate.

Furthermore, hand sanding is not about brute force but rather about finesse and delicacy. It involves a variety of strokes, pressures, and sandpaper grits, each chosen for specific parts of the floor and types of wood. This versatility allows for bespoke finishes that celebrate, rather than conceal, the natural beauty of the wood.

The rhythm of hand sanding is meditative, a stark contrast to the mechanical buzz of power sanders. This slower pace is not a drawback but a feature, allowing for a meticulous and thoughtful approach that pays homage to the wood’s history and potential.

In essence, the art of hand sanding is a dialogue between the craftsman and the wood. It’s a collaboration that respects the past while creating a foundation for the future, ensuring that the wooden floors not only look magnificent but also tell a story of skill, care, and respect.

Benefits of Hand Sanding

Hand sanding, often perceived as a laborious and outdated technique, actually harbours a multitude of benefits that are overlooked in the pursuit of quicker, mechanical methods. Here we explore the advantages that make hand sanding an invaluable tool in the artisan’s repertoire:

1. Superior Precision and Detail

Hand-sanding allows for an unparalleled level of precision and attention to detail. The manual control enables the sander to work closely with the wood’s grain, edges, and unique contours. This precision is especially beneficial when working with intricate designs or delicate areas where a machine could be too aggressive or imprecise.

2. Customisation and Adaptability

Every floor has its own character and challenges. Hand sanding offers the flexibility to adapt to these variances in real-time. It allows the artisan to adjust their technique based on the wood’s response, ensuring a custom finish that respects and enhances the wood’s natural beauty. This adaptability is crucial in restoration projects where preserving original features is paramount.

3. Preserving the Character of the Wood

Unlike machine sanding, which can sometimes strip away more than just the old finish, hand sanding is gentle and controlled. It can preserve the patina and character that make a wooden floor unique, maintaining the depth and history embedded in the wood.

4. Health and Environmental Advantages

Hand sanding produces less dust and noise compared to its mechanical counterpart. This not only creates a healthier environment for the craftsman but also reduces the impact on the surrounding area. The reduced dust also means a clearer view of the work in progress, allowing for finer control and immediate adjustments.

Hand sanding vs. machine sanding

When it comes to finishing floors, the debate between hand sanding and machine sanding is one of tradition versus technology. Each method has its proponents and its specific use cases, and understanding the differences is key to choosing the right approach for any flooring project.

1. Efficiency and Speed

Machine-sanding is known for its efficiency and speed. Power sanders can cover large areas in a fraction of the time it takes to do the job by hand. This makes them ideal for large, open areas where time is of the essence. However, this speed can sometimes be a double-edged sword, as it can lead to over-sanding or uneven results if not handled with care.

2. Control and Precision

Hand sanding excels in control and precision. It allows for a level of detail that machines simply cannot match, particularly in tight spaces, around edges, and in areas requiring delicate handling. For projects that demand a high degree of craftsmanship or for floors with intricate designs, hand sanding is often the preferred choice.

3. Finish Quality

The quality of the finish can vary significantly between the two methods. Machine sanding, while efficient, can sometimes leave swirl marks or uneven textures, especially if the sander is not expertly handled. Hand sanding, on the other hand, offers a more uniform finish, with the ability to smoothly blend areas together and respect the wood’s natural grain.

4. Scope of Application

Machine sanding is typically used in the initial stages of floor refinishing, where removing old finishes or levelling the floor is required. Hand sanding, however, is often reserved for the final stages, where a fine, artisanal finish is desired. It is also the preferred method for antique or delicate floors that could be damaged by the aggressiveness of a machine.

5. Environmental Impact

From an environmental perspective, hand-sanding is less intrusive. It generates less noise pollution and lower levels of dust, making it a more sustainable and health-conscious choice, particularly in residential settings or occupied buildings.

Essential Tools for Hand Sanding

Hand sanding, while simple in concept, requires a specific set of tools to ensure effectiveness, efficiency, and comfort. The right tools not only make the job easier but also contribute to a superior finish. Here is a list of essential tools for hand sanding:

1. Sandpaper

The cornerstone of hand-sanding is sandpaper. It comes in various grits, from coarse (low numbers like 40 or 60) for initial sanding to fine (high numbers like 220 or above) for finishing touches. Quality sandpaper with a good grit range is essential for achieving the desired smoothness without damaging the wood.

2. Sanding Blocks

Sanding blocks provide an even pressure distribution, reducing hand fatigue and helping to avoid uneven sanding marks. They come in various sizes and materials, and some can be custom-made to fit specific contours or shapes on a floor.

3. Steel Wool

For ultra-fine sanding, especially between coats of finish, steel wool (often grade 000 or 0000) is invaluable. It’s ideal for smoothing out minor blemishes and preparing the surface for subsequent coats of varnish or sealant.

4. Dust Masks and Respirators

Sanding can produce a significant amount of dust, which can be harmful if inhaled. A good-quality dust mask or respirator is essential for health and safety, especially when working in enclosed spaces.

5. Safety Glasses

Protecting the eyes from dust particles is crucial. Safety glasses should be worn at all times to prevent any wood dust or debris from causing eye injuries.

6. Work Gloves

Durable work gloves can help protect the hands from splinters and blisters during prolonged sanding sessions. They also provide a better grip on the sandpaper or sanding block.

7. Lighting

Good lighting is essential for hand sanding, as it helps to highlight any imperfections or missed spots on the floor. Portable lamps or adjustable work lights can provide the necessary illumination.

8. Dust Collection Tools

While hand sanding produces less dust than machine sanding, some form of dust collection, such as a vacuum or a dust brush, is still beneficial for keeping the work area clean and minimising the inhalation of dust particles.

Techniques and Tips for Effective Hand Sanding

Hand sanding is an art that requires not only patience and attention to detail but also a mastery of certain techniques and tips to ensure a flawless finish. Here are some key techniques and tips for effective hand sanding:

1. Start with Coarser Grits

Begin with coarser grit sandpaper to remove old finishes, scratches, or imperfections, and gradually work your way up to finer grits. This stepwise approach helps to create a smooth base for the final finish.

2. Sand with the Grain

Always sand in the direction of the wood grain, not against it. Sanding against the grain can create scratches and damage the wood’s natural pattern, which are difficult to remove later.

3. Use the Right Pressure

Apply even pressure throughout the sanding process. Too much pressure can gouge the wood, while too little may be ineffective. The goal is to remove just the right amount of material with each pass.

4. Keep Moving

Avoid staying in one spot for too long, as this can create dips or uneven surfaces. Keep the sanding motion continuous and cover the entire area evenly.

5. Check Your Progress

Regularly wipe the surface with a clean cloth to remove dust and check your progress. This will help you spot any missed areas or imperfections that need further attention.

6. Change the sandpaper regularly.

Don’t hesitate to change your sandpaper once it becomes clogged or worn. Fresh sandpaper is more effective and will make the job easier and quicker.

7. Use Sanding Blocks for Flat Surfaces

For flat surfaces, use a sanding block to ensure an even and flat finish. This helps prevent rounding over the edges and maintains the integrity of the surface.

8. Hand Sand Corners and Edges Carefully

For corners and edges, switch to hand sanding or use smaller, custom-made sanding tools. These areas require more precision and are often where the most attention to detail is needed.

9. Be patient

One of the most important aspects of hand-sanding is patience. Rushing the process can lead to mistakes and a less than satisfactory finish. Take your time to achieve the best results.

10. Final Inspection

After completing the sanding process, do a thorough inspection in good lighting to ensure that the entire surface is uniformly smooth and ready for finishing.

Conclusion

Wood Floor Hand sanding, in the realm of floor finishing, is more than just a technique; it’s a symbol of dedication to quality and craftsmanship. Despite the advancements in mechanical sanding technologies, the benefits of hand sanding remain clear and invaluable. Its ability to achieve superior precision, adapt to the unique character of each wood floor, and preserve the inherent beauty of the wood sets it apart as an essential skill in the artisan’s toolkit.

The contrast between hand sanding and machine sanding is not just about the methods used but also about the philosophy behind the work. Hand sanding embodies a respect for the material, a commitment to craftsmanship, and a desire to produce work that is not only functional but also aesthetically pleasing and long-lasting. It’s a method that harkens back to a time when each stroke of the sandpaper was a stroke of artistry, and each finished floor was a testament to the skill and patience of the craftsman.

Incorporating the right tools and techniques, as outlined, can transform hand sanding from a mundane task to an enjoyable and rewarding process. It’s an opportunity to engage intimately with the material, understand its nuances, and contribute to creating a piece of lasting beauty.

Get more floor restoration advice…

Sanding

We provide virtually dust-free sanding with our continuous belt machinery with mobile extraction units, giving you a safer environment for your family.

Oiling

This organic finish not only adds beauty to your home but also has exceptional water-repellent characteristics, making it easier to clean and maintain.

Waxing

This natural floor finish offers the softest and most mellow appearance – and leaves your floor able to breath.

Buffing

Using soft buffing machines (and hand-polishing where required) will bring a wonderful sheen to your newly-finished floor.

Repairs

We offer a full assessment of your wooden floors to determine what repairs are needed to provide the perfect working surface for the later stages of sanding, staining and sealing.

Restoration

We offer a comprehensive restoration process designed to address floors that are improperly fitted or damaged over time through wear and tear.

Request a fixed price quote for your wood floor restoration now

Simply enter your postcode below to get started.

Services

Wood Floor Sanding Wood Floor Restoration Wood Floor Scratch Repair Squeaky Wood Floor Repair Parquet Floor Sanding Parquet Floor Restoration Commercial Floor Sanding Church Floor Sanding Community Centre Floor Sanding School Floor Sanding Gap Filling Gap Filling with ResinCopyright © Mr Sander®

Privacy & Cookies Terms & Conditions Complaints Procedure Cancellation Rights Sitemap