London:

Nationwide:

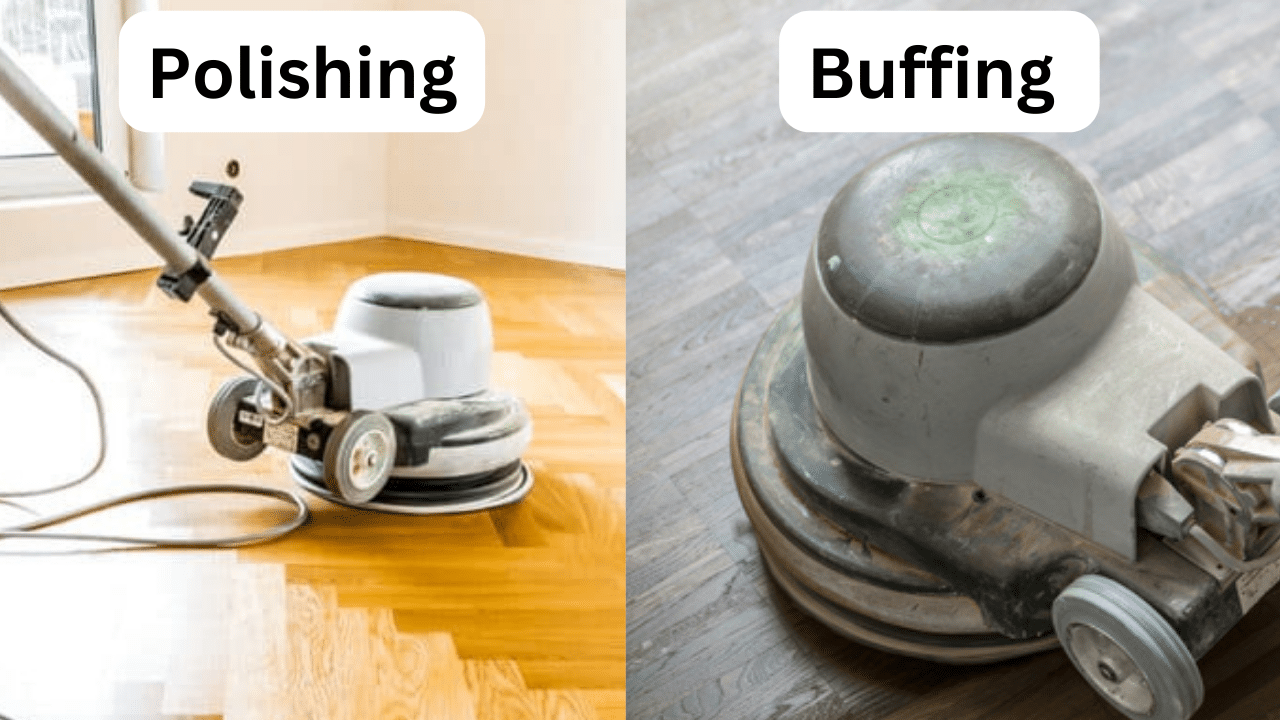

Buffing vs Polishing: What’s the Difference?

Posted on October 9, 2023

Buffing

Exploring The Difference Between Buffing vs Polishing

The timeless beauty of wooden floors has graced homes for centuries, imparting warmth and elegance to any space. But over time, even the most exquisite wood floors can lose their lustre due to daily wear, minor scratches, and scuffs. As a homeowner or property manager, it’s crucial to understand the best methods for maintaining and restoring that radiant shine. Among the most commonly debated techniques in floor care are buffing and polishing. Although often used interchangeably by many, these two processes have distinct differences, both in their methods and the results they yield.

Buffing and polishing are integral parts of wood floor maintenance, but each serves a unique purpose. Buffing primarily focuses on cleaning the floor’s surface and preparing it for further treatments or coatings, while polishing aims to restore the floor’s shine and smoothness. Misunderstanding the distinction between the two can lead to inappropriate care, which might not provide the desired finish or could potentially harm the wood’s surface.

In this comprehensive guide, we’ll delve deep into the nuances of wood floor buffing and polishing, breaking down their respective processes, benefits, and ideal scenarios for each. As you make your way through, you’ll be better equipped to decide which method is best suited for your wooden floors, ensuring they remain a stunning feature of your home for years to come.

Introduction to Surface Finishing

Wooden floors have been a hallmark of elegance and durability for ages, gracing homes, offices, and various spaces with their natural charm. As versatile as wood is in its raw form, the true essence of its beauty and longevity often emerges with the right surface finishing. A finished wood floor not only looks more appealing but also offers better protection against daily wear, moisture, and potential damage. Wood floor surface finishing is an art and science combination tailored to enhance the natural grain, colour, and character of the wood while also providing a functional layer of protection.

The world of wood floor finishes is vast and varied, offering a plethora of choices ranging from penetrating oils and waxes to surface finishes like polyurethanes and varnishes. Each type of finish has its own unique set of properties, methods of application, and aesthetic outcomes. Some finishes sink deep into the wood to nourish and protect from within, while others form a resilient top layer that guards against external factors. Making an informed choice about the right finish is crucial, as it affects the wood’s appearance, feel, maintenance requirements, and longevity.

Whether you’re a homeowner looking to refurbish an old wooden floor, a professional aiming to broaden your knowledge, or someone merely curious about the world of woodwork, this guide to wood floor surface finishing will provide a comprehensive overview. We’ll explore the various types of finishes available, their pros and cons, application techniques, and tips for maintenance, ensuring your wooden floors remain an enduring testament to nature’s splendour and human craftsmanship.

What is buffing?

Buffing is a surface finishing process designed to smooth and polish a substrate, enhancing its shine and luster. While the term is commonly associated with wood flooring, buffing can also be applied to metals, plastics, and other materials to achieve a fine, reflective finish. By eliminating minor scratches, scuffs, and imperfections on the surface, buffing rejuvenates the appearance and helps in creating an even texture.

Purpose of Buffing:

- Revitalization: Over time, surfaces, especially wood floors, accumulate minor scratches, scuffs, and signs of wear. Buffing helps to minimise these imperfections, rejuvenating the appearance of the surface.

- Preparation: Before applying a new finish or coating, buffing prepares the wood by creating a smooth and even surface, ensuring better adhesion to subsequent treatments.

- Enhanced Shine: By polishing the surface to a fine finish, buffing enhances its reflective properties, giving wood floors, metals, or other substrates a glossy, attractive shine.

- Maintenance: Regular buffing can prolong the life of finishes, making them more resilient against wear and tear and reducing the frequency of more intensive restorative processes.

Tools and Materials:

- Buffing Machine: This is the primary tool used, often known as a floor buffer or rotary floor machine. It consists of a large, round pad that rotates at a set speed.

- Buffing Pads: These come in various materials and levels of abrasiveness, from soft wool to more abrasive synthetic pads. The choice of pad depends on the desired outcome and the material being buffed.

- Buffing Compounds: These are substances used in conjunction with the buffing pad to aid in the polishing process. They can range from abrasive compounds for heavy-duty buffing to finer polishes for a mirror-like finish.

- Protective Gear: Safety goggles, dust masks, and ear protection are essential, especially when buffing large areas or using machines that produce noise and dust.

Buffing Techniques:

- Dry Buffing: This technique uses no liquids. The buffing machine, equipped with the appropriate pad and compound, is run over the surface to achieve the desired finish.

- Spray Buffing: A liquid spray, typically a combination of cleaning agents and polishing compounds, is applied to the surface during the buffing process. This helps in both cleaning and shining the surface in one step.

- Sequential Buffing: For deeper scratches or more refined finishes, a sequential process is used. Buffing starts with a coarser pad and compound, gradually moving to finer ones until the desired finish is achieved.

- Overlap Technique: To ensure even buffing, the machine is moved in a path that slightly overlaps the previous one, ensuring no part of the surface is missed.

Buffing is both a science and an art. While understanding the tools and techniques is essential, achieving the perfect finish often comes down to experience and a keen eye for detail. Proper buffing can breathe new life into tired surfaces, making them shine with renewed brilliance.

What is polishing?

Polishing is a procedure used to create a smooth and shiny surface by rubbing or using a chemical action. Like buffing, polishing can enhance the reflectivity and appearance of a material. While both terms are sometimes used interchangeably, polishing usually refers to a process that uses finer abrasives and produces a glossy, mirror-like finish. It’s applicable to a wide range of materials, including wood, metal, stone, and glass.

Purpose of polishing:

- Enhanced Aesthetics: Polishing amplifies the inherent beauty of a material, giving it a bright, reflective finish that adds to its aesthetic appeal.

- Surface Protection: A polished surface often resists dirt and contaminants better than an untreated one, ensuring longevity and reducing maintenance needs.

- Refinement: After preliminary processing or finishing, polishing refines the surface to eliminate minor imperfections and inconsistencies.

- Increased Cleanliness: On metals and stones, a polished surface can be easier to clean and sanitise, which is especially vital in environments like kitchens or medical facilities.

Tools and Materials:

- Polishing Machine: This can range from rotary tools for small projects to large industrial machines for extensive surfaces.

- Polishing Pads: Available in various materials and densities, these pads are selected based on the material being polished and the desired finish.

- Polishing Compounds: These are abrasive substances that facilitate the polishing process. Their grit size can range from coarse to ultra-fine, depending on the stage of polishing and the finish desired.

- Protective Gear: As with buffing, safety goggles, dust masks, gloves, and ear protection are crucial to ensuring safe operations.

Polishing Techniques:

- Wet polishing: Water or another lubricant is used to keep the surface and pad cool, reduce dust, and help in achieving a finer finish. This method is common for stone and certain metals.

- Dry polishing: Conducted without any lubricant, this method is often quicker and can be preferable for materials or situations where moisture could be problematic.

- Sequential Polishing: Starting with a coarser grit compound and moving to progressively finer grits ensures a refined, high-gloss finish.

- Random Orbital Polishing: Using machines that move in random patterns can reduce the chances of swirl marks or patterns being left on the polished surface.

- Hand polishing: For delicate or intricate items, hand polishing with cloths or hand pads can provide more control and precision.

In essence, polishing is a meticulous process aimed at elevating the innate beauty of materials. Whether it’s the sheen of a freshly polished stone countertop, the gleam of polished metal, or the rich glow of wood, the right polishing technique can transform a surface from dull and ordinary to radiant and captivating.

Key Differences between Buffing and Polishing

Buffing and polishing are closely related surface finishing processes, but they serve distinct purposes and employ different techniques. Here are the key differences between the two:

- Purpose:

- Buffing: aimed at smoothing out minor imperfections and creating a uniform surface. It’s often used as a preparatory step for polishing or before applying a finish.

- Polishing: Focuses on creating a shiny, mirror-like finish. It refines the surface further than buffing.

- Finish:

- Buffing: Produces a satin, semi-gloss, or matte finish, depending on the buffing compound and pad used.

- Polishing: Yields a high-gloss, mirror-like finish.

- Abrasive Grain Size:

- Buffing employs compounds with relatively larger abrasive grains. It’s less aggressive than polishing.

- Polishing: uses compounds with very fine abrasive grains, ensuring a smoother, shinier surface.

- Tools and Compounds:

- Buffing: Buffing machines with various pads (often softer) are used in combination with slightly coarser compounds.

- Polishing: Polishing machines, which might be similar to buffing machines but often run at different speeds, use pads designed for polishing in tandem with fine-grit compounds.

- Procedure:

- Buffing typically involves fewer steps and might be quicker, as the focus is on smoothing out the surface rather than achieving a high shine.

- Polishing often involves multiple stages, starting with coarser compounds and progressing to ultra-fine ones to achieve the desired gloss.

- Applications:

- Buffing is commonly used on wood floors, metals before they are polished, and even certain plastics to remove light scratches or prepare the surface for another treatment.

- Polishing is widely used on metals (like car exteriors), stones (like marble or granite countertops), wood for a glossy finish, and more.

- Depth of Action:

- Buffing: While it does remove a tiny amount of material to even out imperfections, buffing is generally less aggressive than polishing.

- Polishing: More material might be removed during polishing, especially during the initial stages, to achieve a flawless, mirror-like finish.

In summary, while both buffing and polishing aim to enhance a material’s surface, they differ in their methods, intensity, and outcomes. Understanding these differences is crucial for selecting the right procedure for a given application, ensuring optimal results and material longevity.

Which one should you choose?

The choice between buffing and polishing depends on several factors, including the desired finish, the current state of the surface, and the material in question. Here’s a guide to help you decide:

- Desired Finish:

- For a satin, semi-gloss, or matte finish, buffing is your best bet.

- If a high-gloss, mirror-like finish is what you’re aiming for, polishing is the route to take.

- Current Surface State:

- If the surface has minor scratches, scuffs, or imperfections, buffing can address these issues effectively.

- For deeper scratches or when a pristine, refined finish is desired, polishing (often preceded by buffing) is more appropriate.

- Maintenance and upkeep:

- Buffing can be a more regular maintenance activity to keep a surface looking good without significantly altering its appearance.

- Polishing might be done less frequently, serving as a more intensive treatment to refresh and revitalise a surface.

- Material Considerations:

- Some delicate or softer materials might not tolerate the more aggressive nature of polishing and would be better suited for buffing.

- Harder materials, like certain metals and stones, can benefit significantly from polishing, yielding a brilliant shine.

- Time and cost:

- Buffing is typically quicker and may be more cost-effective, especially for routine maintenance.

- Polishing, given its multi-stage nature, can be more time-consuming and potentially more expensive.

Common Misconceptions:

- Interchangeable Terms: Many people believe that buffing and polishing are the same. While they’re related, they serve different purposes and yield different finishes.

- Material Removal: A common misconception is that buffing doesn’t remove any material from the surface. In reality, both buffing and polishing remove material, but polishing often removes more due to its finer abrasives and more intensive process.

- Tools and Compounds: It’s a myth that the same tools and compounds can be used interchangeably for both processes. While there is some overlap, specific pads and compounds are designed for buffing versus polishing to achieve the desired results.

- Polishing Equals Protection: Some believe that a polished surface is always more protected than a buffed one. While polishing can offer some protection due to its smoothness, it doesn’t replace the need for protective coatings or treatments, especially on materials prone to oxidation or damage.

- One-Time Procedure: Many think that once a surface is buffed or polished, it won’t need further treatment. Both processes, especially buffing, might need to be repeated periodically to maintain the appearance and protect the surface.

Conclusion

In the realm of surface finishing, both buffing and polishing play pivotal roles in enhancing and preserving the beauty of various materials. While they share similarities in their objectives of refining surfaces, they distinctly differ in their techniques, outcomes, and applications. Buffing serves as a means to smooth out minor imperfections and create uniformity, often acting as a preparatory step for other treatments. In contrast, polishing aims for the pinnacle of surface refinement, yielding a mirror-like, high-gloss finish.

Choosing between these two methods isn’t about superiority, but rather suitability. Factors such as the material in question, the desired aesthetic outcome, maintenance considerations, and even budget constraints can influence this choice. Amidst the myriad of options and techniques available, understanding the nuances of buffing and polishing ensures that surfaces are treated with the care and expertise they deserve.

Furthermore, dispelling common misconceptions surrounding these processes is crucial for informed decision-making. It’s essential to approach surface finishing with a blend of knowledge, experience, and a clear vision of the end goal. In doing so, one can harness the transformative power of buffing and polishing, bringing out the best in every material and ensuring its longevity and allure for years to come.

Get more floor restoration advice…

Sanding

We provide virtually dust-free sanding with our continuous belt machinery with mobile extraction units, giving you a safer environment for your family.

Oiling

This organic finish not only adds beauty to your home but also has exceptional water-repellent characteristics, making it easier to clean and maintain.

Waxing

This natural floor finish offers the softest and most mellow appearance – and leaves your floor able to breath.

Buffing

Using soft buffing machines (and hand-polishing where required) will bring a wonderful sheen to your newly-finished floor.

Repairs

We offer a full assessment of your wooden floors to determine what repairs are needed to provide the perfect working surface for the later stages of sanding, staining and sealing.

Restoration

We offer a comprehensive restoration process designed to address floors that are improperly fitted or damaged over time through wear and tear.

Request a fixed price quote for your wood floor restoration now

Simply enter your postcode below to get started.

Services

Wood Floor Sanding Wood Floor Restoration Wood Floor Scratch Repair Squeaky Wood Floor Repair Parquet Floor Sanding Parquet Floor Restoration Commercial Floor Sanding Church Floor Sanding Community Centre Floor Sanding School Floor Sanding Gap Filling Gap Filling with ResinCopyright © Mr Sander®

Privacy & Cookies Terms & Conditions Complaints Procedure Cancellation Rights Sitemap